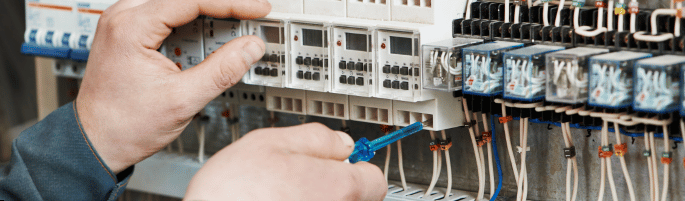

Industrial Electrician

The Industrial Electrician course is tailored for individuals who want to specialize in the electrical systems used in industrial settings. This advanced course covers the installation, maintenance, and repair of electrical systems and equipment in manufacturing and industrial environments. Students will learn about complex electrical systems, automation, and safety protocols essential for working in industrial facilities.

What you'll learn?

- Advanced electrical systems and industrial machinery

- Installation and maintenance of industrial electrical equipment

- Troubleshooting and repairing complex electrical faults

- Understanding of industrial electrical codes and standards

- Use of advanced diagnostic tools and equipment

- Electrical safety practices and risk assessment

- Automation systems and control panels

- Electrical load management and circuit design

- Preventive maintenance techniques for industrial equipment

- Effective communication and teamwork in an industrial setting

Course summary:

The Industrial Electrician course equips students with the expertise needed to manage and repair electrical systems in industrial environments. The course combines theoretical knowledge with practical training, focusing on advanced electrical systems, automation, and safety. Graduates will be well-prepared to handle the complexities of industrial electrical systems and ensure smooth operations within manufacturing and production facilities.

- Comprehensive training on industrial electrical systems and machinery

- Proficiency in troubleshooting and repairing industrial equipment

- Skills in automation and control panel systems

- Hands-on experience with real-world industrial projects

- Emphasis on electrical safety and effective communication in industrial settings

Practical training:

- Hands-on practice with industrial electrical equipment and machinery

- Real-time projects involving installation, maintenance, and repair

- Workshops on using advanced diagnostic tools and equipment

- Training in automation systems and control panel setup

- Exercises in electrical safety and risk management

- Field visits to industrial facilities for practical experience

- Projects on preventive maintenance and system optimization

- Collaboration and communication training for industrial environments

Course syllabus:

- Overview of industrial electrical systems

- Roles and responsibilities of an industrial electrician

- Career pathways and opportunities in industrial electrical work

- Personal Protective Equipment (PPE) for electricians

- Safe working practices and procedures

- Workplace safety regulations and standards (e.g., OSHA, NEC)

- Hazard identification, risk assessment, and mitigation in electrical work

- Basic electrical theory (e.g., Ohm’s Law, AC/DC circuits)

- Electrical units and measurements (e.g., voltage, current, resistance)

- Understanding power generation, transmission, and distribution

- Identifying and understanding electrical components (e.g., resistors, capacitors, inductors)

- Working with electrical devices (e.g., motors, transformers, relays)

- Introduction to control systems and PLCs (Programmable Logic Controllers)

- Reading and interpreting electrical diagrams and schematics

- Wiring techniques for industrial installations

- Conduit bending and installation

- Troubleshooting and repairing electrical circuits

- Installing and maintaining electrical systems and equipment

- Performing preventive maintenance on electrical systems

- Diagnosing and repairing electrical faults and malfunctions

- Using diagnostic tools and equipment (e.g., multimeters, oscilloscopes)

- Understanding motor control circuits and components

- Installing and maintaining motor starters and drives

- Troubleshooting motor control systems

- Introduction to variable frequency drives (VFDs)

- Basics of PLCs and their applications in industrial settings

- Programming and configuring PLCs

- Troubleshooting PLC-controlled systems

- Integrating PLCs with other control systems

- Understanding local and international electrical codes and standards (e.g., NEC, IEC)

- Compliance with industry standards and regulations

- Environmental considerations in electrical installations

- Introduction to renewable energy systems (e.g., solar, wind)

- Installing and maintaining renewable energy systems

- Integrating renewable energy with existing electrical systems

- Troubleshooting renewable energy systems

- Effective communication with supervisors and team members

- Coordination with other trades and project schedules

- Handling emergency situations and evacuation procedures

- Interacting with clients and stakeholders professionally

- Understanding project requirements and timelines

- Providing accurate reports and documentation

- Understanding electrical service agreements and contracts

- Invoicing and payment procedures

- Maintaining professionalism and ethical conduct in the workplace

- Practical training sessions on electrical installations and repairs

- Simulation exercises for real-world scenarios

- Role-playing communication and coordination challenges

- Continuing education opportunities and certifications (e.g., IEC, NABCEP)

- Staying updated with advancements in electrical technology

- Promoting ethical conduct and sustainability in electrical work

- Written and Practical Examinations

- Continuous Assessment through Assignments and Projects

- Certification upon Successful Completion

Career Scope:

Upon completion of the Industrial Electrician course, graduates can explore career opportunities in various sectors, including:

- Industrial manufacturing and production facilities

- Automation and control systems companies

- Energy and utility companies

- Industrial maintenance and repair services

- Construction and renovation projects

- Government and municipal industrial departments

- Electrical equipment and machinery manufacturers

- Technical support and consulting firms

- Safety and compliance organizations

- Large-scale industrial and commercial facilities