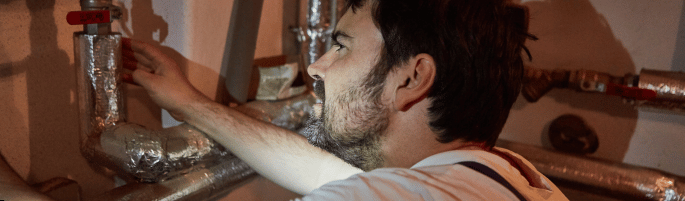

Pipe Fitter

The Pipe Fitter course is designed to provide comprehensive training for individuals interested in specializing in the installation, assembly, and maintenance of piping systems. This course covers essential skills needed to work with various pipe materials and systems, focusing on precision, safety, and efficiency. Students will learn how to fit and secure pipes in residential, commercial, and industrial settings.

What you'll learn?

- Basics of pipe fitting and installation techniques

- Understanding different types of piping materials (metal, plastic, etc.)

- Reading and interpreting blueprints and technical drawings

- Cutting, threading, and joining pipes

- Installation of pipe supports, hangers, and brackets

- Techniques for pipe alignment and adjustment

- Safety protocols and best practices in pipe fitting

- Maintenance and repair of pipe systems

- Troubleshooting and resolving pipe fitting issues

- Understanding codes and standards for pipe installation

Other Plumbing & Irrigation courses:

Course summary:

The Pipe Fitter course provides in-depth training in the installation and maintenance of piping systems. Students will gain hands-on experience with various pipe materials and techniques, learn to interpret technical drawings, and apply safety protocols. The course is designed to prepare graduates for a successful career in pipe fitting, emphasizing both practical skills and theoretical knowledge.

- Comprehensive training in pipe fitting techniques and materials

- Proficiency in reading blueprints and technical drawings

- Skills in cutting, threading, and joining pipes

- Knowledge of safety protocols and pipe system maintenance

- Hands-on experience with real-world pipe fitting projects

Practical training:

- Hands-on practice with pipe fitting and installation techniques

- Real-time projects involving the assembly and maintenance of piping systems

- Workshops on cutting, threading, and joining pipes

- Exercises in interpreting blueprints and technical drawings

- Training in safety practices and installation standards

- Field visits to construction sites for practical experience

- Projects on pipe alignment, adjustment, and repair

- Application of industry codes and standards in real-world scenarios

Course syllabus:

- Overview of pipe fitting in various industries (e.g., construction, oil and gas, plumbing)

- Importance of accurate pipe fitting and installation

- Roles and responsibilities of a pipe fitter

- Career pathways and opportunities in pipe fitting

- Personal Protective Equipment (PPE) for pipe fitters

- Safe operating practices and procedures

- Workplace safety regulations and standards (e.g., OSHA, ANSI)

- Hazard identification, risk assessment, and mitigation in pipe fitting operations

- Understanding different types of pipes (e.g., steel, copper, PVC, PEX)

- Properties and applications of various pipe materials

- Selection of pipes based on project requirements and specifications

- Handling and storage of pipe materials

- Essential tools for pipe fitting (e.g., pipe wrenches, cutters, threading machines)

- Proper use, maintenance, and storage of pipe fitting tools

- Familiarization with advanced equipment (e.g., welding machines, bending tools)

- Emergency procedures and shutdown protocols

- Measuring, cutting, and threading pipes accurately

- Bending and shaping pipes using appropriate tools

- Joining pipes using various methods (e.g., welding, brazing, soldering, mechanical joints)

- Ensuring leak-proof connections and fittings

- Understanding and interpreting pipe fitting blueprints and schematics

- Marking and layout techniques for pipe installation

- Identifying pipe routes and installation points

- Coordinating with other trades and services on site

- Installation of complex piping systems (e.g., HVAC, fire protection, industrial systems)

- Fabrication and pre-assembly of pipe sections

- Working with high-pressure and high-temperature pipes

- Techniques for pipe system maintenance and repair

- Conducting visual and pressure tests on installed pipes

- Identifying and rectifying defects and leaks

- Documenting inspection results and ensuring compliance with standards

- Regular maintenance and inspection schedules

- Understanding local and international regulations for pipe fitting

- Compliance with industry standards (e.g., ASME, ASTM, ISO)

- Environmental considerations in pipe fitting operations

- Effective communication with site supervisors and team members

- Coordination with construction schedules and project requirements

- Handling emergency situations and evacuation procedures

- Interacting with clients and stakeholders professionally

- Understanding project timelines and deadlines

- Providing accurate work reports and documentation

- Understanding pipe fitting contracts and agreements

- Invoicing and payment procedures

- Maintaining professionalism and ethical conduct in the workplace

- Practical training sessions on pipe fitting techniques

- Simulation exercises for real-world scenarios

- Role-playing communication and coordination challenges

- Continuing education opportunities and certifications (e.g., NCCER)

- Staying updated with advancements in pipe fitting technology

- Promoting ethical conduct and sustainability in pipe fitting operations

- Written and Practical Examinations

- Continuous Assessment through Assignments and Projects

- Certification upon Successful Completion

Career Scope:

Upon completing the Pipe Fitter course, graduates can explore career opportunities in various sectors, including:

- Construction companies

- Industrial manufacturing plants

- Plumbing and pipe fitting services

- Oil and gas industry

- Utility companies (water, sewage, etc.)

- HVAC and refrigeration companies

- Municipal maintenance departments

- Engineering and design firms

- Environmental services companies

- Government agencies (regulation and oversight)