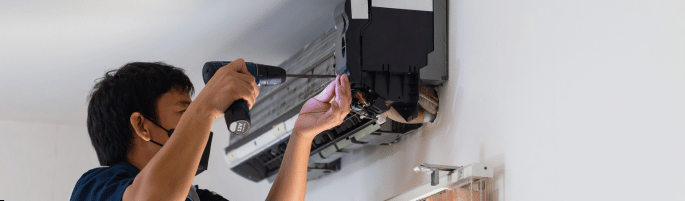

Service Technician for Air Conditioners

The Service Technician for Air Conditioners course is designed for individuals who wish to specialize in the maintenance, repair, and servicing of air conditioning systems. This course covers everything from the fundamentals of air conditioning technology to advanced diagnostic techniques. Students will learn how to efficiently troubleshoot issues, perform repairs, and ensure optimal performance of air conditioning units in residential and commercial settings.

What you'll learn?

- Basics of air conditioning systems and components

- Installation and setup of air conditioning units

- Troubleshooting common air conditioning problems

- Techniques for refrigerant handling and charging

- Repair and replacement of faulty components

- Preventive maintenance practices for air conditioners

- Understanding air flow, temperature control, and energy efficiency

- Safety protocols for working with electrical and refrigerant systems

- Use of diagnostic tools and equipment

- Customer service and communication skills

Other courses of Service technicians for Home appliances:

Course summary:

The Service Technician for Air Conditioners course provides comprehensive training in the operation, maintenance, and repair of air conditioning systems. Students will develop a solid understanding of air conditioning technology and gain hands-on experience with various diagnostic and repair techniques. The course emphasizes practical skills and safety, preparing graduates to excel in the HVAC industry.

- Detailed instruction on air conditioning systems and components

- Proficiency in troubleshooting, repairing, and maintaining air conditioners

- Skills in refrigerant handling and system diagnostics

- Knowledge of energy efficiency and temperature control

- Hands-on experience with real-world air conditioning repair projects

Practical training:

- Hands-on practice with air conditioning installation and maintenance

- Real-time projects involving troubleshooting and repairing air conditioning units

- Workshops on refrigerant handling and charging techniques

- Exercises in using diagnostic tools and equipment

- Training in safety practices and industry standards

- Field visits to HVAC service sites for practical experience

- Projects on preventive maintenance and efficiency optimization

- Customer service role-playing and communication skills training

Course syllabus:

- Overview of air conditioning principles and components

- Types of air conditioning systems (e.g., split, window, central)

- Importance of proper maintenance and service

- Career pathways and opportunities in HVAC service

- Personal Protective Equipment (PPE) for HVAC technicians

- Safe handling of refrigerants and chemicals

- Workplace safety regulations and standards (e.g., EPA, OSHA)

- Hazard identification, risk assessment, and mitigation

- Essential tools for air conditioner servicing (e.g., gauges, thermometers, vacuum pumps)

- Diagnostic equipment (e.g., leak detectors, manifold gauges)

- Proper use, calibration, and maintenance of tools

- Selection of tools based on service requirements

- Understanding the refrigeration cycle and principles

- Refrigerants types and properties (e.g., R-410A, R-22)

- Pressure-enthalpy diagrams and temperature-pressure relationships

- Handling and recovering refrigerants safely

- Installation requirements and procedures

- Proper positioning and mounting of indoor and outdoor units

- Refrigerant charging and system startup procedures

- Testing for leaks and system performance verification

- Routine maintenance tasks (e.g., filter cleaning, coil cleaning)

- Inspection of electrical components (e.g., capacitors, relays)

- Lubrication of moving parts (e.g., fan motors, bearings)

- Preventive maintenance schedules and checklists

- Common air conditioner problems and their causes

- Use of diagnostic tools and techniques (e.g., pressure testing, airflow measurement)

- Systematic troubleshooting approach (e.g., electrical, mechanical, refrigeration issues)

- Identifying and rectifying faults in compressors, condensers, and evaporators

- Understanding electrical schematics and wiring diagrams

- Testing and troubleshooting electrical circuits

- Control systems (e.g., thermostats, relays, contactors)

- Installation and calibration of electronic controls

- Environmental impact of HVAC operations

- Energy efficiency principles and practices

- HVAC system optimization and performance enhancement

- Compliance with energy efficiency regulations (e.g., SEER ratings)

- Interacting with clients and stakeholders professionally

- Explaining service findings and recommendations

- Providing maintenance tips and usage guidelines

- Handling customer complaints and feedback

- Estimating service costs and preparing quotations

- Invoicing and payment procedures

- Maintaining professionalism and ethical conduct in the workplace

- Practical training sessions on air conditioner servicing

- Simulation exercises for real-world scenarios

- Role-playing communication and troubleshooting challenges

- Continuing education opportunities and certifications (e.g., NATE, HVAC Excellence)

- Staying updated with advancements in HVAC technology

- Promoting ethical conduct and sustainability in HVAC service practices

- Written and Practical Examinations

- Continuous Assessment through Assignments and Projects

- Certification upon Successful Completion

Career Scope:

Upon completing the Service Technician for Air Conditioners course, graduates can explore career opportunities in various sectors, including:

- HVAC service companies

- Residential and commercial air conditioning services

- Industrial facilities and manufacturing plants

- Property management companies

- Energy efficiency and consulting firms

- Retail and service centers for air conditioning units

- Refrigeration and air conditioning repair services

- Construction and renovation companies

- Government and municipal maintenance departments

- Technical support and customer service roles in HVAC